Shopping cart

0

Product

Products

(empty)

No products

To be determined

Shipping

€ 0,00

Total

Product successfully added to your shopping cart.

Quantity

Total

There are 0 items in your shopping cart. There is 1 item in your shopping cart.

Total products

(tax excl.)

Total shipping (tax excl.)

To be determined

Total

(tax excl.)

WB: System WBS800 for factory filling of wooden frame elements (complete system)

8934

New product

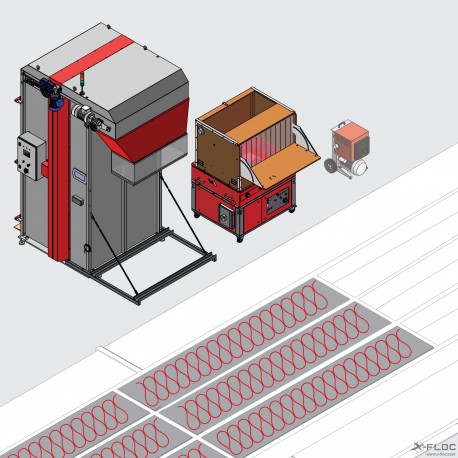

WB: System WBS800 for factory filling of wooden frame elements (complete system)

Details

Complete factory filling system including insulation blowing machine, blowing panel based on 5 spring-mounted blow-out nozzles and big bale milling machine with weighing, automatic logging of all relevant blow-in parameters and the installed insulation masses, incl. 40m transport hose (with earthing strand) and 50m connecting line between blow-in machine and blow-in panel.

The factory filling system consists of components which can be used individually and complies with the applicable machinery directive (CE conformity). The system, which is linked from several components, forms an independent system which also has CE conformity.

Technical data for the entire system:

- Production capacity between 500 and 1,800 kg/h, depending on the insulation material used and the installation density selected.

- Continuous pipe cross-section of NW90 (3½'') (blow-out connection blow-in machine - hose line - blow-in plate).

Technical data blow-in plate EP800:

Technical data:

- Dimensions (standard): approx. 3,000x900x500mm (LxWxH, different lengths possible, see options and "Technical data blow-in plate EP800").

- Weight: approx. 280-400kg (depending on length and options)

- Power supply: 230V/50Hz/16A

- Compressed air power supply: filtered compressed air required, pressure 6-10 bar at approx. 55l/min

- Number of spring-loaded injection nozzles: 5 pieces (different number possible/required, see options)

- Hose connection and internal tubing: NW90 (3½'')

- Throughput: depending on the blow-in thermal insulation material used and the upstream blow-in machine, up to 1,800kg/h

- Control: PLC panel PC (Beckhoff) with touch display (alternatively with wireless tablet PC on request).

- Quality control: Automatic in conjunction with optional weighing unit of the blow-in machine or GBF or GBA or GBL

- Networking with X-Floc blow-in machines for an automatic blow-in process possible.

- Blowing-in process: System-guided / Automatic

Factory filling plant, consisting of:

01. EM 430-400V/9,5kW High-powered insulation blowing machine (prod. No. 5802)

02. EM4XX/5XX: Additional option DS - Adjustable airlock rotation speed (prod. No. 5060)

03. EM4XX: Additional package for integrating the insulation blowing machine into a factory filling system (prod. No. 8615)

04. Control cable 50m for interlinking EM4XX -- Blowing panel (prod. No. 8618)

05. WB: EP800-NW90-Blowing Panel for industrial element filling (prod. No. 7992)

06. Control cable 5m for interlinking EM4XX -- Bale conditioning machine (prod. No. 8619)

07. EP: Additional package for integrating the insulation blowing panel (EP) into a factory filling system (prod. No. 8617)

08. WB: GBF1050 Bale Conditioning Machine (prod. No. 4628)

09. GBF1050: Additional package for integrating the bale conditioning machine into a factory filling system (prod. No. 8616)

10. WB: GBF Underframe insulation blowing machine (prod. No. 4439)

11. WB: GBF weighing system with increased precision (prod. No. 8157)

12. Auswertegerät 82b-1: Addon-Card analog output (prod. No. 9833)

13. WB: GBF1050 Access ramp for GBF with weighing system (prod. No. 8127)

14. Conveyor hose NW90 (3½'') with flexible earthing braids, L 20m (2 pieces, prod. No. 8911)

15. Hose connector NW90 (3½'') stainless steel (1 piece, prod. No. 1452)

16. Hose clamp NW90 (3½'') (5 pieces, prod. No. 9908)

Options:

- Protective hose with Velcro fastener for cable package blowing machine - blowing panel (Art. No. 10291, for example 16m)

- EP800: Surcharge for built-in panel PC with 10.1'' touch screen instead of 7.0" (Art. No. 10843)

- EP800: Extension by up to 500mm (surcharge) (Art. No. 11035)

- EP800: Extension with 1 piece injection module (Art. No. 11030)

- VS: Amplifier station module amplifier VS40 (Art.-Nr. 10309) or VS: Amplifier- / Suction station VS55 mobil (Art.-Nr. 9455) of VS: Amplifier- / Suction station VS75 mobil (Art.-Nr. 9793), recommended for the processing of wood fibre and rock wool for hose length

The factory filling system consists of components which can be used individually and complies with the applicable machinery directive (CE conformity). The system, which is linked from several components, forms an independent system which also has CE conformity.

Technical data for the entire system:

- Production capacity between 500 and 1,800 kg/h, depending on the insulation material used and the installation density selected.

- Continuous pipe cross-section of NW90 (3½'') (blow-out connection blow-in machine - hose line - blow-in plate).

Technical data blow-in plate EP800:

Technical data:

- Dimensions (standard): approx. 3,000x900x500mm (LxWxH, different lengths possible, see options and "Technical data blow-in plate EP800").

- Weight: approx. 280-400kg (depending on length and options)

- Power supply: 230V/50Hz/16A

- Compressed air power supply: filtered compressed air required, pressure 6-10 bar at approx. 55l/min

- Number of spring-loaded injection nozzles: 5 pieces (different number possible/required, see options)

- Hose connection and internal tubing: NW90 (3½'')

- Throughput: depending on the blow-in thermal insulation material used and the upstream blow-in machine, up to 1,800kg/h

- Control: PLC panel PC (Beckhoff) with touch display (alternatively with wireless tablet PC on request).

- Quality control: Automatic in conjunction with optional weighing unit of the blow-in machine or GBF or GBA or GBL

- Networking with X-Floc blow-in machines for an automatic blow-in process possible.

- Blowing-in process: System-guided / Automatic

Factory filling plant, consisting of:

01. EM 430-400V/9,5kW High-powered insulation blowing machine (prod. No. 5802)

02. EM4XX/5XX: Additional option DS - Adjustable airlock rotation speed (prod. No. 5060)

03. EM4XX: Additional package for integrating the insulation blowing machine into a factory filling system (prod. No. 8615)

04. Control cable 50m for interlinking EM4XX -- Blowing panel (prod. No. 8618)

05. WB: EP800-NW90-Blowing Panel for industrial element filling (prod. No. 7992)

06. Control cable 5m for interlinking EM4XX -- Bale conditioning machine (prod. No. 8619)

07. EP: Additional package for integrating the insulation blowing panel (EP) into a factory filling system (prod. No. 8617)

08. WB: GBF1050 Bale Conditioning Machine (prod. No. 4628)

09. GBF1050: Additional package for integrating the bale conditioning machine into a factory filling system (prod. No. 8616)

10. WB: GBF Underframe insulation blowing machine (prod. No. 4439)

11. WB: GBF weighing system with increased precision (prod. No. 8157)

12. Auswertegerät 82b-1: Addon-Card analog output (prod. No. 9833)

13. WB: GBF1050 Access ramp for GBF with weighing system (prod. No. 8127)

14. Conveyor hose NW90 (3½'') with flexible earthing braids, L 20m (2 pieces, prod. No. 8911)

15. Hose connector NW90 (3½'') stainless steel (1 piece, prod. No. 1452)

16. Hose clamp NW90 (3½'') (5 pieces, prod. No. 9908)

Options:

- Protective hose with Velcro fastener for cable package blowing machine - blowing panel (Art. No. 10291, for example 16m)

- EP800: Surcharge for built-in panel PC with 10.1'' touch screen instead of 7.0" (Art. No. 10843)

- EP800: Extension by up to 500mm (surcharge) (Art. No. 11035)

- EP800: Extension with 1 piece injection module (Art. No. 11030)

- VS: Amplifier station module amplifier VS40 (Art.-Nr. 10309) or VS: Amplifier- / Suction station VS55 mobil (Art.-Nr. 9455) of VS: Amplifier- / Suction station VS75 mobil (Art.-Nr. 9793), recommended for the processing of wood fibre and rock wool for hose length